Everything You Need to Know about Micro-Soldering Services in Vancouver revolves around the specialized techniques and tools used in the repair of tiny electronic components on circuit boards.

This service is particularly beneficial for small electronic devices with complex circuitry, including smartphones, laptops, and other gadgets. Micro-soldering involves the use of specific tools such as microscopes, rework stations, hot air stations, and precise soldering irons.

Technicians follow a step-by-step process, from identifying and removing defective parts to soldering replacement components with precision.

Safety precautions are important during micro-soldering, and professionals ensure a well-ventilated workspace and proper protective gear. Micro-soldering services cater to the growing demand for complicated electronic repairs.

What is Micro Soldering?

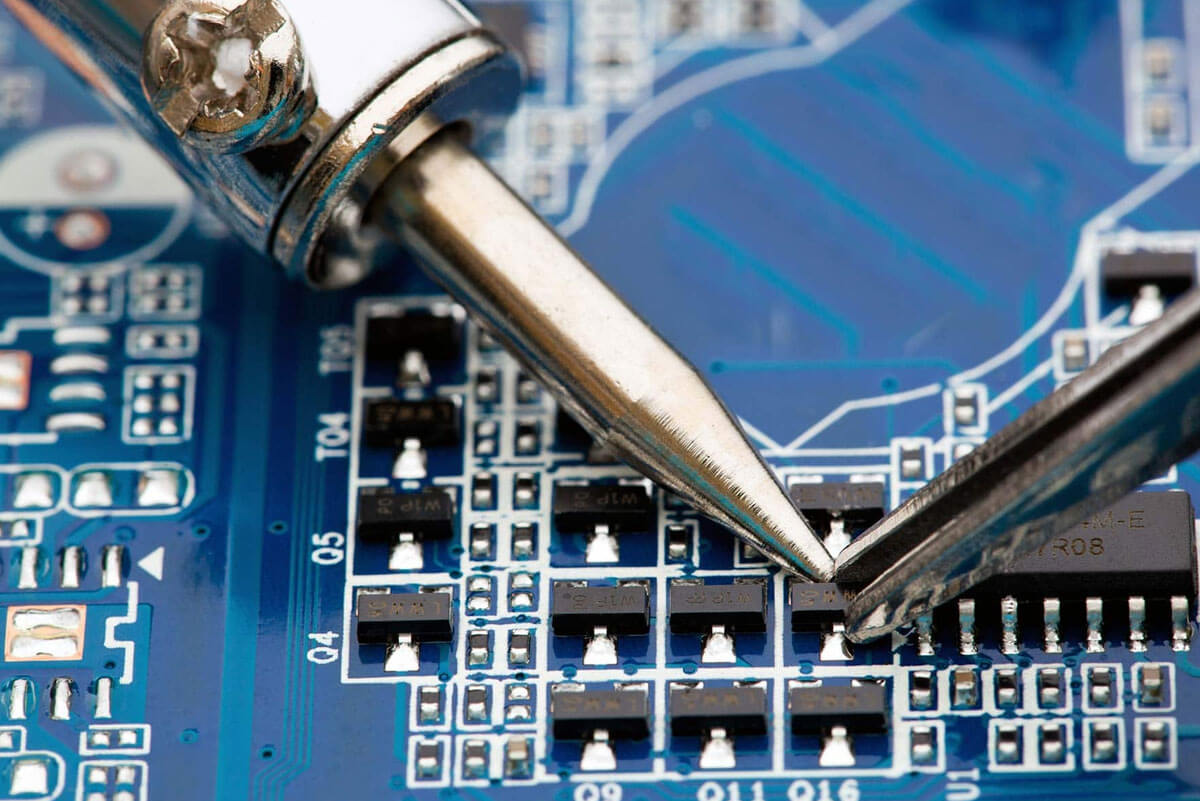

Micro-soldering is a precise soldering technique used to repair tiny electronic components on circuit boards. Unlike traditional soldering, which deals with larger components, micro-soldering focuses on the repair of delicate and intricate parts such as microchips, connectors, and small resistors.

This specialized micro-soldering service in Vancouver is required for fixing various electronic devices like smartphones, laptops, and other gadgets.

Tools and Equipment:

- Micro Soldering Microscope: A high-quality microscope is essential for magnifying tiny components and ensuring precision during the soldering process. Micro-soldering microscopes provide the required clarity and visibility to work on intricate details.

- Micro Soldering Rework Station: This station combines a soldering iron and a hot air gun, allowing technicians to handle both precision soldering and desoldering tasks efficiently. It offers temperature control, ensuring that delicate components are not damaged during the process.

- Micro Soldering Hot Air Station: The hot air station is instrumental in reflowing solder, allowing components to be placed or removed without causing damage. It provides a controlled stream of hot air that is crucial for working on small and delicate components.

- Micro Soldering Iron: A micro-soldering iron is designed for precision soldering services on tiny electronic components in Vancouver. It typically features a fine tip and precise temperature control, ensuring accuracy in the soldering process.

- Micro Soldering Multimeter: A multimeter is indispensable for measuring electrical values and diagnosing faults in electronic circuits. In micro-soldering, a multimeter helps in ensuring that the repaired components meet the required specifications.

- Micro Soldering Software: Specialized software aids in diagnosing and troubleshooting electronic devices. Technicians use software tools to identify faults, assess circuitry, and ensure that the repaired components function as intended.

Tips on How to Micro Solder:

Here are a few steps which are followed in order to perform micro-soldering services in Vancouver:

Step 1: Remove Defective Part:

Identify and carefully remove the defective component using the appropriate tools, such as tweezers and a desoldering braid.

Step 2: Preparation for Repair:

Clean the area around the soldering point and ensure that the circuit board is free from any contaminants or debris that could interfere with the soldering process.

Step 3: Preparing to Solder:

Apply a small amount of flux to the soldering area to promote better solder flow and improve the adhesion of the solder to the components.

Step 4: Secure the Component:

Use a set of precision tweezers to secure the replacement component in place. Proper alignment is necessary for a successful job.

Step 5: Trim to Fit:

Trim any excess leads from the soldered component using fine-tipped cutters. It will ensure a neat and tidy job.

Step 6: Examine the Board with a Microscope:

After soldering, carefully inspect the repaired area using a microscope to ensure that the solder joints are clean, well-formed, and free from defects.

Safety Precautions to Follow while Micro Soldering:

- Always work in a well-ventilated area to avoid inhaling fumes produced during soldering.

- Use proper safety gear, including gloves and safety glasses. These protect you against burns and eye injuries.

- Ensure that the work area is well-lit to facilitate accurate soldering and inspection.

- Turn off equipment when not in use to prevent accidents and conserve energy.

Conclusion

Micro-soldering services in Vancouver play an important role in the domain of electronic repairs, offering precise solutions for complex parts. Armed with specialized tools, skills, and a commitment to safety, technicians can successfully learn about the complexities of micro-soldering, ensuring that electronic devices are restored to optimal functionality.

FAQs:

Q: How much do micro-soldering services in Vancouver typically cost?

A: The cost of micro-soldering services varies depending on the complexity of the repair and the specific components involved. You are advised to consult with a reputable repair shop for accurate pricing.

Q: Can any electronic device benefit from micro-soldering services?

A: Micro soldering is really beneficial for small electronic devices such as smartphones, tablets, laptops and other gadgets. It is not limited to a specific type of device but is more dependent on the nature of the repair required.

Q: Is micro-soldering a DIY-friendly task, or should it be left to professionals?

A: Micro-soldering requires specialized skills, tools, and knowledge. While some individuals with advanced soldering experience may attempt small-scale repairs, it is generally recommended to seek the expertise of professionals.